MALAYSIA PORT

One of the Malaysia Port renowned for its cutting-edge facilities, advanced equipment, and comprehensive information technology systems, seamlessly integrates all port users into its operations.

The port takes pride in delivering dependable, efficient, and state-of-the-art services to major shipping lines and container operators. This commitment ensures that shippers, both domestically and internationally, enjoy extensive connectivity to the global market at Malaysia Port. This integration facilitates the smooth movement of cargoes, providing customers and business partners with a distinct advantage in their operations.

PROJECT INTRODUCTION

Description

1. This Malaysia port established operating for over 23 years since its establishment on 13 March 2000, is embarking on a comprehensive project to upgrade its lighting infrastructure. The existing light fittings in major equipment have become old and worn out, necessitating a modernization effort.

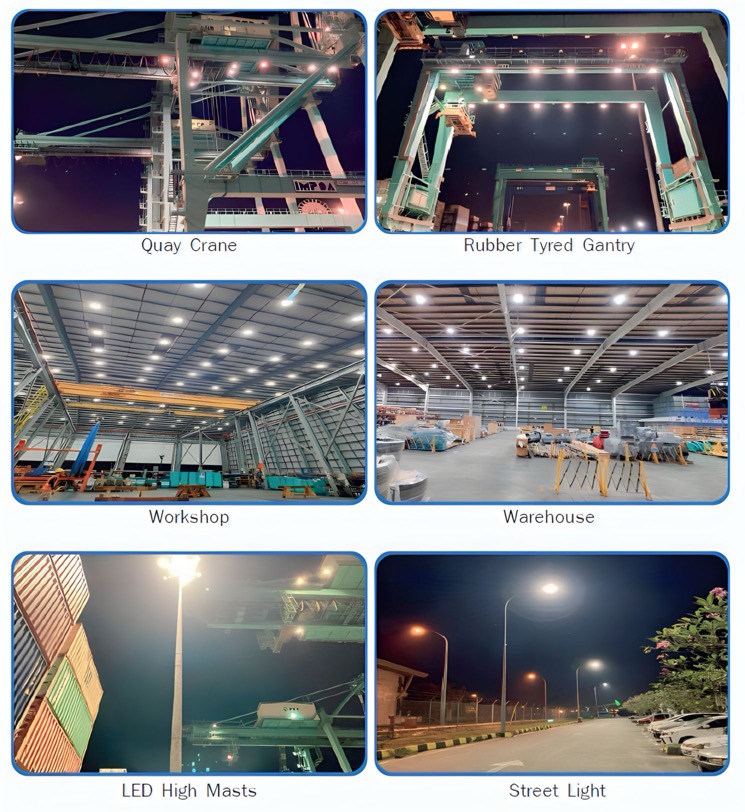

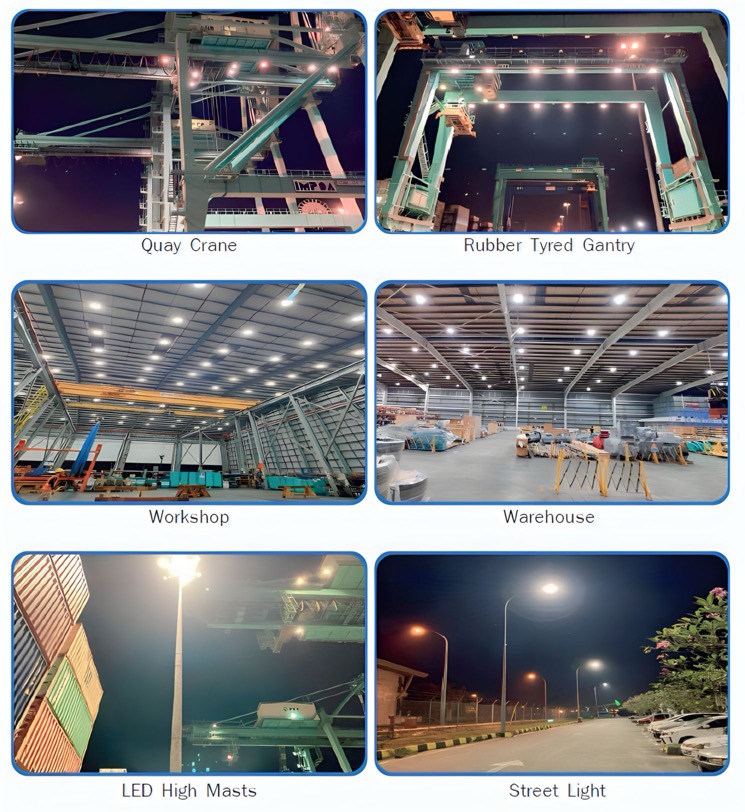

2. The project is divided into two main divisions. The first division focuses on the primary equipment of the port, namely the quay crane (QC) and rubber-tyred gantry (RTG). To ensure optimal lighting for these critical areas, new LED flood lights have been installed. In this scope of work, a total of 35 sets of QCs and 35 sets of RTGs have been upgraded, resulting in the installation of 557 units of LED Flood Light Fitting (16°) at the QCs and 496 units of LED Flood Light Fitting (45°) at the RTGs

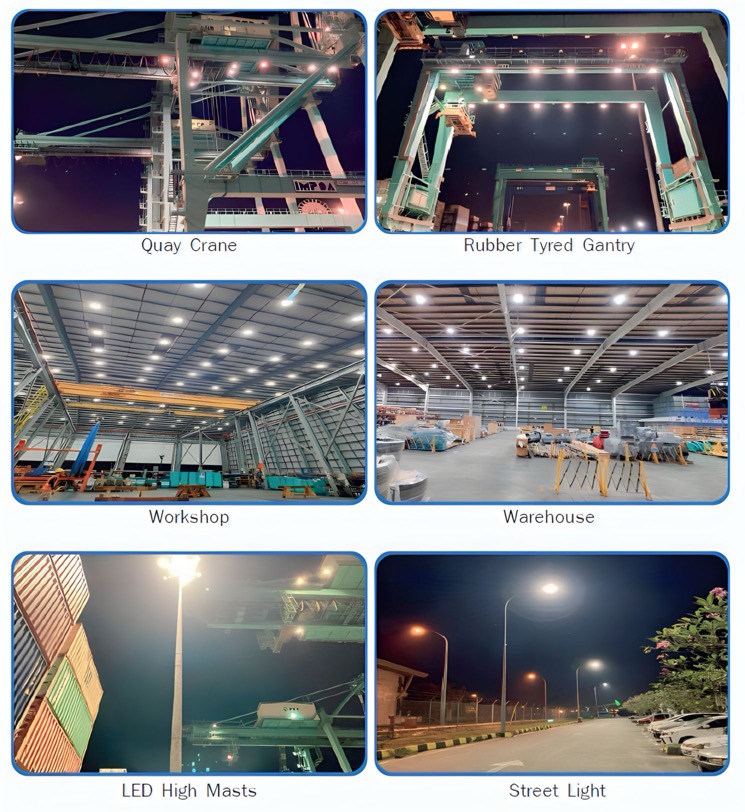

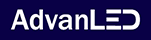

3. The second division encompasses various areas, including the new engineering workshop, Warehouse DW4, and street lighting within and outside the port which covers Wisma A and B. The wharf area is also covered in this scope of work. To provide efficient illumination in these spaces, LED High Bay Light Fittings, LED Street Light Fittings and LED High Mast Light Fittings have been strategically installed. A total of 426 LED High Bay Light Fittings have been deployed, 271 LED Street Light Fittings positioned both within and outside the port premises and along with 338 LED High Mast Light Fittings installed on 20 poles at the wharf.

4. By upgrading the lighting infrastructure aimed to enhance visibility, safety, and operational efficiency within its facilities. This project represents a significant investment in modernizing the port’s lighting systems to meet the growing demands of a dynamic and bustling port environment.

Scope of Work

1. This port established port with a history spanning over 23 years since its establishment on 13 March 2000, is currently immersed in an all-encompassing initiative to enhance its lighting infrastructure. The existing light fittings on major equipment have reached a state of aging and wear, necessitating a crucial modernization effort.

2. Breakdown of the activities and documents involved:

-

- Project Schedule

- Sample Simulation

- Method of Statement (MOS)

- Manual of related certificates for LED

- Factory Acceptance Test (FAT)

- HSE Plan

- Mobilization and Installation

- Inspection Test Plan (ITP) and Daily Reports

- Work completion report

- Project Claims (Progressively)

Project Planning Process

1. Unpredictable weather conditions posed a major challenge, causing disruptions and delays in project tasks. Adjustments to the schedule were essential for maintaining safety and efficiency during installation.

2. The project’s location within an active port area presented additional hurdles. Work interruptions occurred as the team had to wait for cargo unloading, requiring tools and equipment to be set aside until port activities were completed.

3. Considering these challenges, the revised completion duration for the project is set at 9 months.

4. Effective project management and communication with the client facilitated agreement on the adjusted timeline, ensuring the successful and timely completion of the project.

CHALLENGES

1. To meet the specific requirements of the port, we had to customize the light fitting brackets for LED Flood Lights and the LED High Mast Light Fitting. Initially, the brackets were made of mild steel, and the mounting holes were at different locations. However, this port requested that stainless steel brackets be painted with epoxy paint for enhanced durability and corrosion resistance. This customization involved sourcing stainless steel materials, applying epoxy paint, and adjusting screw holes to ensure that the brackets met Port’s stringent standards. This solution successfully fulfilled Port’s requirements, reducing installation time and effort while ensuring a seamless fit for the lighting fixtures.

2. Achieving certain certifications proved challenging. The IEC 62722, IEC 62717, and Neutral Salt Spray Test require 1000 hours to complete, making it a time-consuming process. Certifications like IK09 and IP66 presented challenges as the required quality was niche, making it difficult to find suitable suppliers. Moreover, the customization of components solely for our project resulted in higher costs.

3. Unforeseen factors, such as adverse weather conditions, the allocation of the port time slots prioritizing ship and container transportation, and festivals, resulted in a delay. The occurrence of festivals added to the challenges, as it affected manpower availability and work schedules. We had to adapt to these circumstances by temporarily suspending work, storing tools and equipment, and resuming installation after the festival period, which further contributed to the overall project timeline.

4. Various installation challenges were encountered during the project:

- QC & RTG :

The light fittings at the QC and RTG are located at an elevated height of above 15m. Thus, to ensure the safety of our workers, our team undergoes comprehensive training such as NIOSH and are taught to strictly adheres to safety protocols especially those outlined in the “Yellow Book”. By following these guidelines and implementing meticulous planning, we prioritize the well-being of our workers and maintain a safe working environment through- out the installation process.

- High Bay :

The use of an electrical boom lift was necessary for installation, as this is the requirement posted by the Pot. However, due to the layout of the warehouse, certain areas were inaccessible using this method, requiring alternative solutions to be devised

- High Mast:

Adjusting the angle of the high mast lighting to meet the required lux level of 30 poses challenges, demanding precise alignment, coordination, and careful calibration of the lighting fixtures. Furthermore, the busy activities at the wharf and yard provide an obstruction to completing the work. - Street Light:

Power supply issues at this port added complexity to the installation and testing process, requiring additional troubleshooting and coordination with port personnel.

5. The port’s strict documentation requirements presented an additional challenge. Extensive attention to detail and thorough documentation were necessary to meet their stringent standards and ensure compliance throughout the project.

Summary

LED Vision Sdn Bhd successfully supplied, delivered, installed, tested, and commissioned LED lights for quay cranes (QC), rubber-tired cranes (RTG), high masts, high bays, and street lights for the port despite the challenges. The upgraded lighting infrastructure has had a positive impact, increasing safety, visibility, and productivity, resulting in client satisfaction. Future collaborations and initiatives are anticipated for further enhancements.